Development And Characterization of High-Performance Lightweight Composites for Aerospace Structures

Keywords:

- Aerospace composites, Carbon fiber, Hybrid laminates, Finite Element Analysis, Mechanical testing, Thermal stability.

Abstract

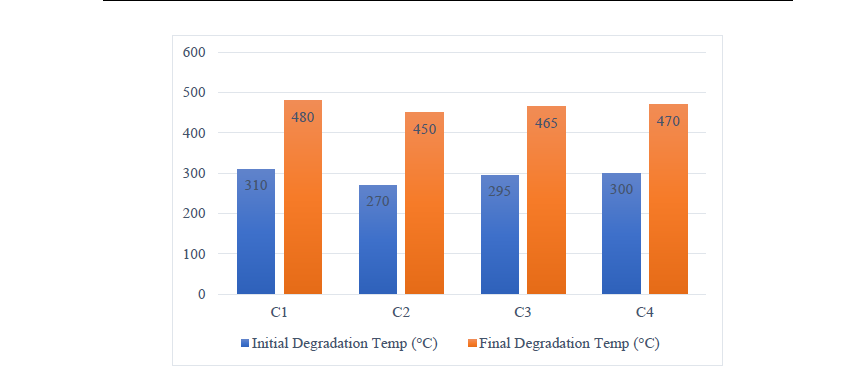

The increasing demand for lightweight, high-strength materials in aviation engineering has led to significant advancements in composite material technology. This paper focusses on the design, production, and research of fiber-reinforced polymer composites that are most appropriate for structural use in aeroplanes. Several fibre types, such as woven glass fibre, unidirectional carbon fibre, and carbon-glass hybrids, were combined with epoxy and polyester matrices to generate composite laminates with different layup configurations. Mechanical properties such as fatigue resistance, elastic modulus, and tensile and flexural strength were experimentally examined using ASTM criteria. Thermal stability was assessed using thermogravimetric analysis (TGA), and fracture reasons were investigated using scanning electron microscopy (SEM). ANSYS Finite Element Analysis (FEA) was used to simulate tensile behaviour and predict failure based on the Tsai-Wu criterion. Carbon fiber/epoxy laminates perform better mechanically and thermally, but hybrid laminates offer a more cost-effective balance between strength and durability. The work highlights the effectiveness of integrated experimental-computational methodologies for advanced material design and confirms that tailored composite systems may meet aeronautical performance requirements.